Zortrax M300

| PRINTING TECHNOLOGY | LPD™ - Layer Plastic Deposition |

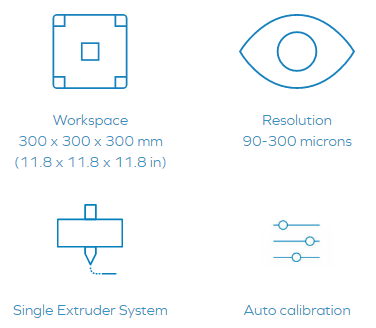

| EXTRUDERS | 1 Single Extruder |

| BUILD VOLUME | 300 x 300 x 300 mm |

| LAYER RESOLUTION | 90-300 microns |

| POSITION PRECISION | 1.5 microns |

| LCD DISPLAY | Yes |

| OPERATING NOZZLE TEMPERATURE | MAX 380° C (716° F) |

| PLATFORM TEMPERATURE | 110° C (230° F) |

| SUPPORTED MATERIALS | Z-ULTRAT, Z-HIPS, Z-GLASS, Z-PETG |

| FILAMENT DIAMETER | 1.75 mm |

| CONNECTIONS | SD card (included) |

| CHASSI | Steel |

| SOFTWARE INCLUDED | Z-Suite® |

| FILE FORMAT | .stl.obj.dxf |

| PRODUCT DIMENSION | 490 x 490 x 590 mm |

| NOZZLE DIAMETER | 0.4 mm |

| SUPPORTED OS | Mac OS X / Windows XP, Windows Vista, Windows 7, Windows 8 |

| SHIPPING WEIGHT | 50 kg (110 lbs) |

Buy this M300 3D printer and get a wonderful machine in Zortrax quality. The M300 comes out of the box plug&play. Operating this device is easy due to its user-friendly interface and slicing software – Z-Suite. Frequent free updates improve Z-Suite functionality.

Main product features:

Buy this M300 3D printer and get a wonderful machine in Zortrax quality. This large brother of the Zortrax M200 has the same powerful plug&play 3D printing abilities. This device is made very solid, easy to use and offers you an excellent additive manufacturing experience. The M300 comes out of the box plug&play. Operating this device is easy due to its user-friendly interface and slicing software – Z-Suite. Frequent free updates improve Z-Suite functionality.

No need to execute a difficult calibration process of the 3D printer or software. Put this 3D printer on your table, upload the model to your slicer and start 3D printing within 2-5 Minutes.

Appropriately selected heating and cooling points in the extruder of the Zortrax M300 solve the frequent problem of inability to release material by the extruder. It can be caused by a change in the physical properties of material associated with temperature.

The use of a two-part platform allows an easy removal of the build platform after the 3D printing process is finished. Thanks to this feature, the finished 3D model can be easily removed without causing any calibration issues or damaging of the component. Perforations on the platform allows to 3D print filament based on ABS which tend to warp. They prevent the model from peeling off during additive manufacturing process. If more adhesion is needed you can use an adhesive.

Additionally, an extra layer of raft is used as a special base for the object. This is very important for 3D printing large models. The build platform is heated to the correct temperature for each type of filament. With the new Z-Suite slicer software you can set the printing bed temperature for third-party filaments on your own. Furthermore, the Zortrax M300 allows a wide range of temperatures (from 20° C to 110° C) to 3D print using many kinds of materials.

The Zotrax M300 is formfitting with an innovative calibration system which enures that the platform is leveled correctly every time. There are five calibrating points located on the platform itself which calculate its exact position. The system can determine on which level the calibrating points should be located. In the case of a slight tilt the extruder adapts to the position of the platform while its putting on the first layers of the model. We recommend you to level the Zortrax M300 after transportation. Simply follow the instructions on the screen and your build platform will be leveled in under 5 minutes. Until you move the 3D printer no further calibration will be needed.

A system of dual X and Y axises leads the extruder with high precision. Stability and quality of 3D printing is greatly improved by using 8 smooth rods. The build platform moves very even and without vibration. This is a key factor for good-quality 3D prints.

Creating support structure is easy thanks to Single Extruder Support system (SES). This feature allows to 3D print support structure for complex models without the need of dual extruder and additional material. With the Zortrax M300 3D printed support structure is easy to remove and efficient. The extruder is optimized to use only the exact amount of filament needed to support the model.

We recommend to 3D print using Z-Filaments with features dedicated for Zortrax® M300. When you manufacture these filaments, nice results are guaranteed. If you like to experiment with materials we suggest you use PrimaVALUE, PrimaSELECT and EasyPrint filaments for good-value and safe 3D printing.

If you are working with ABS or filaments which tend to warp we advise you to upgrade your Zortrax M300 with side covers and covering. This keeps your building chamber warm and minimizes warping.

Additive manufacturing with the large volume 3D printer Zortrax M300 is possible for the creation of prototypes and small-scale production.